TAKENAKA ‘S KOREAN PROJECTS IN EUROPE

35 YEARS OF EXPERIENCE, OVER 130 PROJECTS

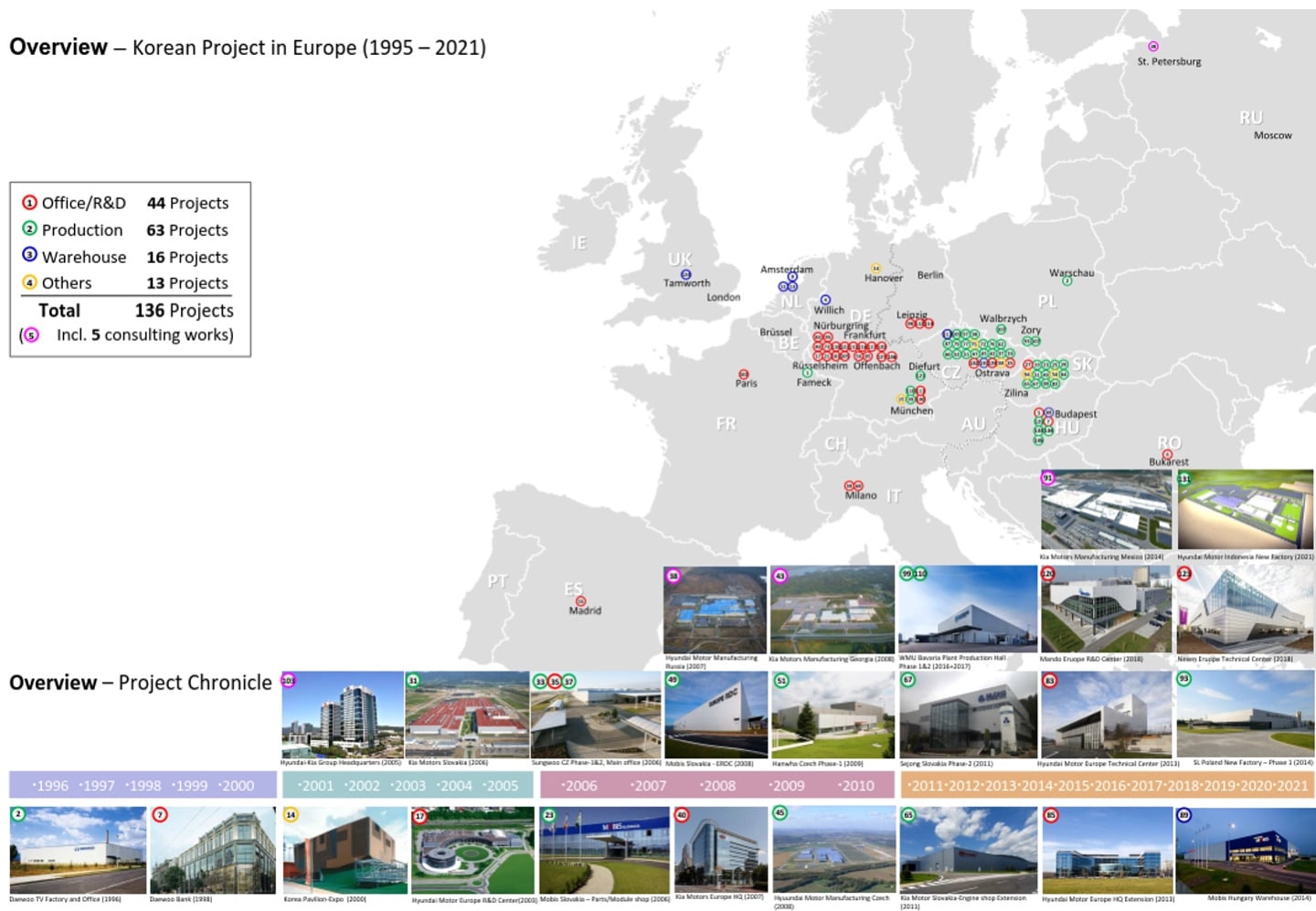

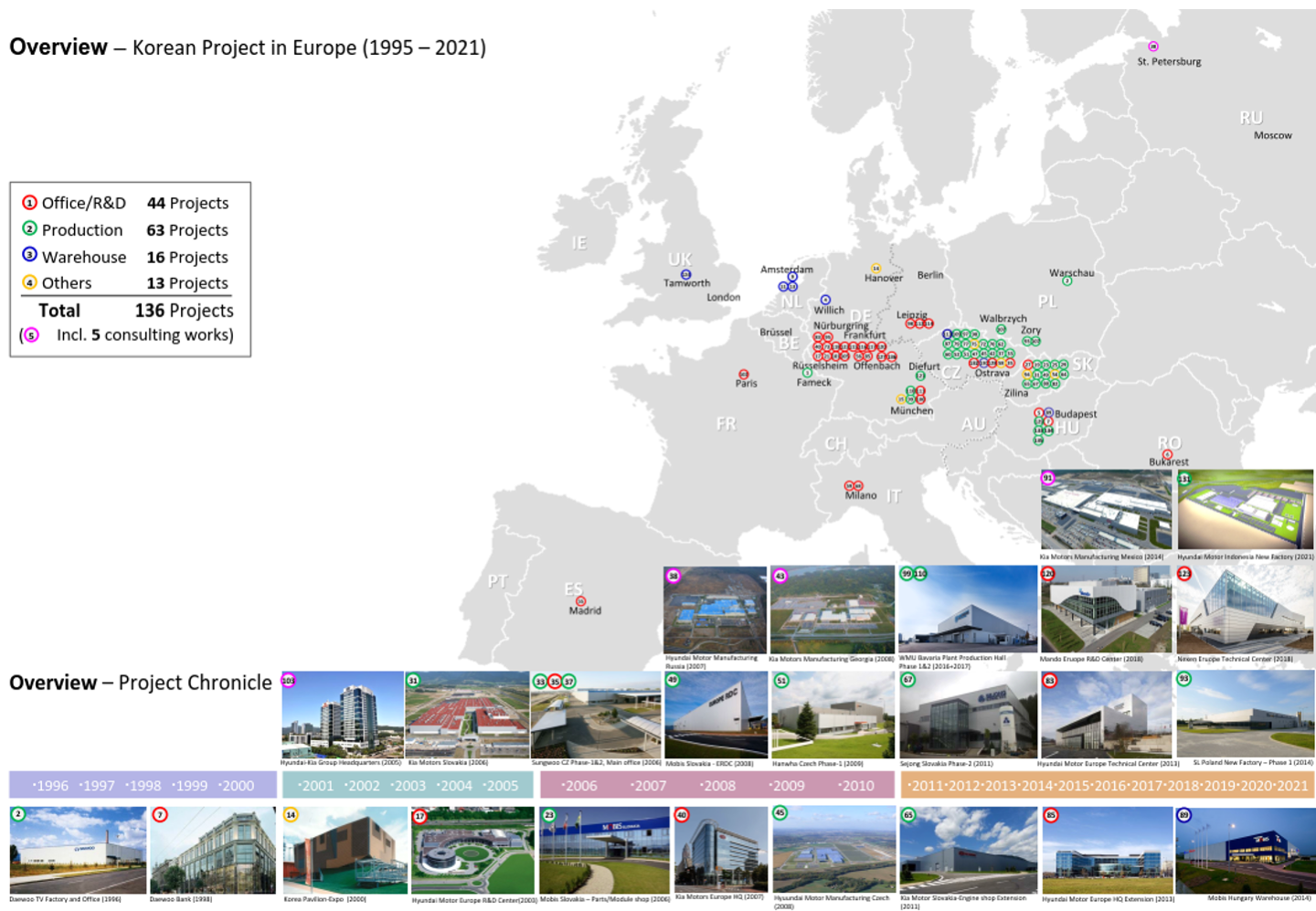

We look back to over 35 years of experience with clients from South Korea and over 130 projects in different European countries. Our first Korean project was a factory for Goldstar (now known as LG Electronics) back in 1987. We accompanied other clients from the electronics manufacturing industry like LG and Daewoo and built factories, warehouses, and offices.

In the 2000s, new international trade orders and block market rules came into effect, and Korean Automotive companies entered the European market. With that our Korean projects shifted mainly to the automotive sector. Hyundai and Kia and many of their supplier companies were among our clients. Next to production plants and warehouses, we built European headquarters, R&D centers, and Design centers. Starting in the 2010s we implemented projects for independent suppliers of the Automotive sector.

In the last three years, we have seen another shift towards the battery industry for electric vehicles (EV). Three Korean companies (LG Energy solution/ Samsung SDI/ SK ON) are at the forefront, being the only ones producing batteries for EVs in Europe so far. With them, many Korean supplier factories are coming to Europe.

TAKENAKA Europe’s projects in the battery sector include:

- Central glass in the Czech Republic, electrolyte production facility (key component of lithium-ion batteries), 2019

- Mercedes Benz manufacturing Poland, EV batteries assembly factory, 2020

- Soulbrain Hungary, electrolyte production facility, 2021

- Toray Industries Hungary, battery separator film (BSF) production factory, 2021

- Three ongoing projects in Hungary and in Slovakia

LOCAL EXPERTISE, ASIAN SERVICE

WHY KOREAN COMPANIES CHOOSE US

In Asia, the customer-oriented approach is part of the culture. The project delivery method and the performance of a general contractor are critical for the success or failure of the project. So, what do Korean clients expect when coming to Europe? And what differentiates TAKENAKA Europe from local contractors?

Reasons that make us a recurring choice for our Korean clients:

- Total management and single point responsibility (from feasibility study to design and construction)

- Regional branches with long term experiences

- Strong local know-how and local networks

- Understanding of the Korean work culture

- Intercultural communication skills

- Customer-tailored service regarding design, budget, and schedule request

- Keeping budget and schedule by management of Korean business unit

WE AIM FOR TRUST, NOT FOR PROJECTS

From the very first project we do for a new Korean client, our goal is to build a trustful relationship.

We apply a client-oriented approach, which results in a win-win for both sides:

- Diverse project delivery schemes with different responsibility models

- Schedule optimization

- Control of budget

- Local competitiveness plus Korean management

Takenaka Europe has been gaining trust from (Korean) clients through the past projects over the years. This reputation was established in Europe and has impacted the ASEAN market as well.

TOTAL PACKAGE

DESIGN & BUILD

FROM FEASIBILITY STUDY TO TURNKEY HANDOVER

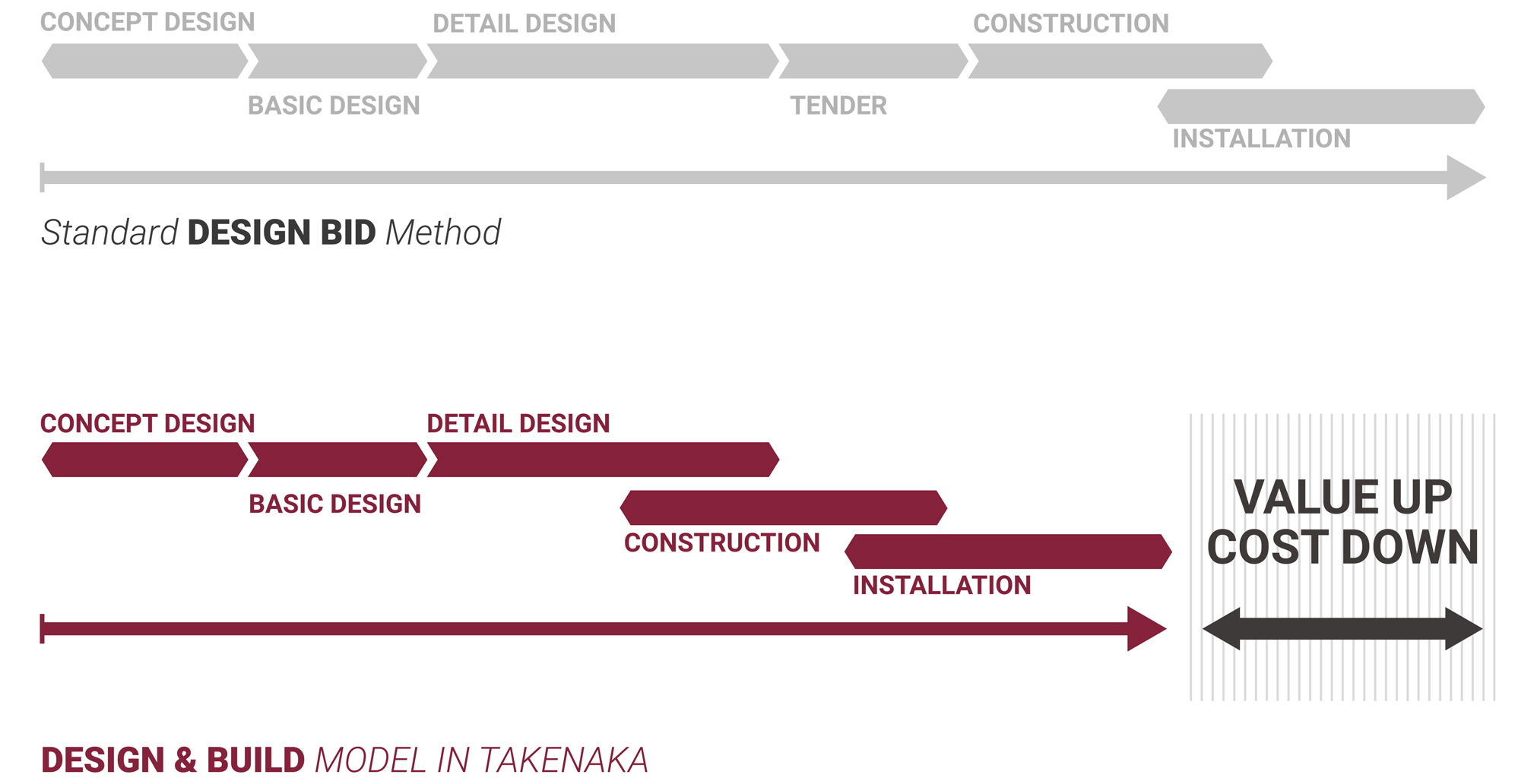

Design & Build is our full-service package: we take care of a project from the idea to the turnkey handover. We manage the entire cycle from the feasibility study, including a budget, schedule, and concept, to the planning and execution. Design & Build is our core competency, and the benefit for the client is to have only one contract partner for the entire process. The client does not have to take on any coordination tasks with local building authorities and subcontractors, and in terms of quality, the client can rely on us.

With in-house architects, engineers, and construction staff, there is organic cooperation between the planning and construction that enables a smooth transition of the different phases. The productivity is raised and results in a shortened project schedule.

SAVES YOUR TIME AND COST

In conclusion, what are the main advantages of the Design & Build approach?

- One point of contact and single point responsibility

- Shortened schedule

- Cost & Quality controls

- Transparent and instantaneous communication

- Smooth transition between various project phases

- Fast reaction regarding changes by client during the construction phase

Learn more about our Korean service here.

“동유럽 공장건설”, “동유럽 인허가”, “헝가리 공장건설”, “헝가리 인허가”, “폴란드 공장건설”, “폴란드 인허가”, “체코 공장건설”, “체코 인허가”, “슬로바키아 공장건설”, “슬로바키아 인허가”, “세르비아 공장건설”, “세르비아 인허가”, “독일 공장건설”, “독일 인허가”, “스페인 공장건설”, “스페인 인허가”